High-Efficiency PET Bottle Flakes Pelletizer

Transform post-consumer PET flakes into high-quality, reusable pellets. Our advanced pelletizing line ensures maximum purity, consistent output, and superior profitability for your recycling operation.

Get a Quote NowWhy Choose Our PET Pelletizing Machine?

We deliver more than just a machine; we provide a complete, profitable plastic recycling solution. Boost your efficiency and output quality from day one.

Superior Performance

Engineered for high throughput and stable operation, minimizing downtime and maximizing your return on investment.

Energy Efficient Design

Advanced heating and motor technology reduces power consumption, lowering your operational costs significantly.

Durable & Reliable

Constructed with wear-resistant alloys for key components, ensuring a long service life for your PET flake granulator.

Intelligent Control

Equipped with a PLC system for one-touch start-up, real-time monitoring, and simplified process control.

From PET Flakes to High-IV Pellets: The Process

Our PET bottle flakes pelletizer automates the entire granulation process, with key steps designed to preserve and enhance the material’s Intrinsic Viscosity (IV).

1. Crystallization

Washed flakes are pre-crystallized to prevent clumping and prepare them for high-temperature extrusion.

2. Extrusion & Degassing

A specialized screw melts the PET. A powerful vacuum degassing system removes moisture, crucial for preventing IV-value degradation.

3. Melt Filtration

A non-stop hydraulic screen changer filters out impurities without interrupting production, ensuring melt purity.

4. Pelletizing & Cooling

The purified melt is extruded into strands, cut into uniform pellets, and rapidly cooled by water.

5. Dewatering & Storage

Pellets are dewatered and sent to a storage silo, ready for use as high-grade raw material.

Advanced Features for Peak Performance

Every component is meticulously engineered for the unique challenges of PET recycling, ensuring quality and durability.

Bimetallic Screw & Barrel

Offers exceptional wear and corrosion resistance, significantly extending service life when processing abrasive PET materials and ensuring consistent melt quality.

High-Efficiency Vacuum Degassing

Multi-stage vacuum system effectively removes volatiles and moisture, which is the key to preventing hydrolytic degradation and maintaining high Intrinsic Viscosity (IV) in pellets.

Non-Stop Hydraulic Screen Changer

Allows for filter screen changes in seconds without interrupting production, maximizing uptime and ensuring a continuous, clean melt flow for higher quality output.

SIEMENS PLC Smart Control

Integrated control system with a user-friendly HMI touch screen allows for one-touch startup, real-time process monitoring, and data logging for quality control.

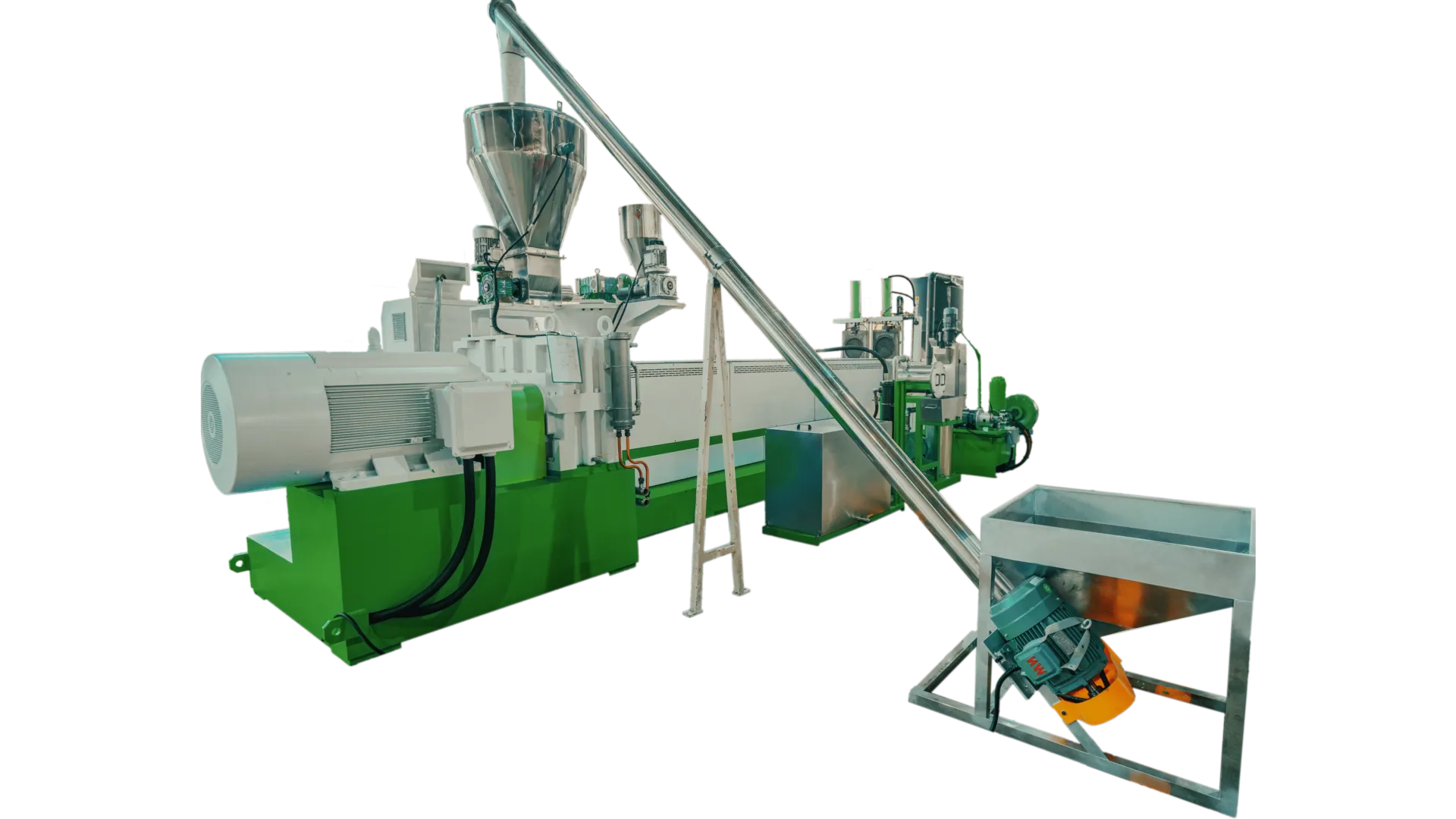

Anatomy of Our PET Pelletizer

Discover the core components that make our PET granulation line a leader in performance, reliability, and final pellet quality.

Specialized Single Screw Extruder

The heart of the system, our extruder is designed specifically for PET. It gently melts pre-compacted flakes and ensures thorough plasticization for a homogenous melt stream.

- Optimized L/D Ratio: Provides superior melting and mixing performance.

- Advanced Degassing: A double-zone vacuum degassing system efficiently removes moisture and volatiles, crucial for maintaining high IV.

- Durable Construction: Built for continuous operation with abrasive materials.

Water-Strand Cutting System

This robust system cools and cuts the extruded plastic into uniform pellets, designed for ease of use and consistent production.

- Stainless Steel Cooling Trough: A 4-meter trough provides ample cooling time. The stainless steel construction prevents rust and contamination.

- High-Speed Pelletizer: Precisely cuts the cooled strands into uniform cylindrical pellets, ready for the next stage.

- Adjustable Design: The system can be adjusted to accommodate different output rates and material properties.

Vibration & Centrifugal Drying System

A multi-stage drying process ensures the final pellets are perfectly prepared for storage and transport, with minimal energy consumption.

- Vibrating Dewatering Screen: The first stage efficiently removes the majority of surface water from the pellets.

- Centrifugal Dryer: A high-speed horizontal centrifugal dryer powerfully expels remaining moisture, resulting in pellets with <1% moisture content.

- Low Labor Cost: This automated system combines dewatering and drying into one seamless, energy-efficient step.

Tailored Solutions for Your Needs

We understand that every recycling operation is unique. We offer customized PET pelletizing lines based on your capacity requirements and material characteristics.

Water-Strand Pelletizing Line

The ideal choice for versatility and ease of operation. This system is robust, easy to maintain, and highly effective for a wide range of output capacities.

- Cost-effective and reliable

- Simple to operate and maintain

- Ideal for capacities from 200 to 1000 kg/h

Water-Ring Pelletizing Line

Designed for higher automation and perfectly uniform pellets. The die-face hot cutting system is fully enclosed, saving space and improving production efficiency.

- Highly automated, saving labor costs

- Produces uniform, spherical pellets

- Compact footprint, ideal for limited space

Technical Specifications: PET Flake Granulator

| Parameter | RTM-PET-100 | RTM-PET-130 | RTM-PET-150 |

|---|---|---|---|

| Screw Diameter | 100 mm | 130 mm | 150 mm |

| Output Capacity | 200-300 kg/h | 300-500 kg/h | 500-700 kg/h |

| Main Motor Power | 55 kW | 90 kW | 132 kW |

| Applicable Material | Washed & Dried PET Bottle Flakes (<1% moisture) | ||

| Pelletizing Type | Water-Strand / Water-Ring (Customizable) | ||

| Control System | SIEMENS PLC with HMI Touch Screen | ||

Proven Performance: Gallery, Video & Applications

See our PET bottle flakes pelletizing machine in detail, watch it in action, and discover the high-value products made from its output.

Watch Our PET Pelletizer in Operation

Final Pellets & Downstream Applications

Get a Customized Solution & Quote

Ready to upgrade your plastic recycling capabilities? Fill out the form below, and our experts will contact you with a tailored proposal for your PET bottle flakes pelletizer needs.

Frequently Asked Questions

The Intrinsic Viscosity (IV) is a measure of the polymer’s molecular weight and is a critical quality indicator for PET. Higher IV values mean better mechanical properties. Our system, especially the degassing stage, is designed to minimize IV loss, ensuring the final pellets are suitable for high-value applications like bottle-to-bottle recycling.

Water-strand pelletizing involves extruding plastic strands into a water bath, which are then cut by a pelletizer. It’s versatile and easy to operate. Water-ring pelletizing is a die-face cutting method where blades cut the pellets directly at the extruder die head, with a water ring for cooling. It’s more automated and produces more uniform, spherical pellets.

Yes, we offer comprehensive after-sales support. This includes worldwide installation, commissioning of the pelletizing line, and operational training for your staff to ensure you can run the equipment efficiently and safely.

No. This pelletizer is designed for the final granulation stage. It requires pre-washed and crushed PET flakes. Contaminants like labels, dirt, and moisture must be removed beforehand. We also provide complete PET bottle washing and recycling lines if you need a full solution.