Biodegradable Plastic Extruders – High-Performance Solutions from Rumtoo

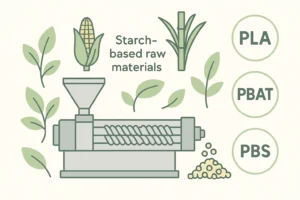

Discover how Rumtoo’s twin screw extruders enable efficient, eco-friendly production of biodegradable plastics like PLA, PBAT, and starch-based compounds. Ideal for packaging, agriculture, and medical applications.