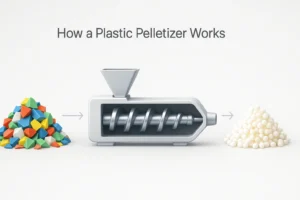

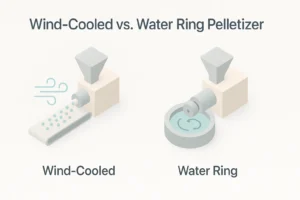

How Does a Plastic Pelletizer Work? A Comprehensive Guide

Discover how a plastic pelletizer works with Rumtoo’s expert guide. We break down the complete pelletizing process—from extrusion and filtration to cutting—to help industrial professionals understand the technology and select the right recycling machinery for their operations.